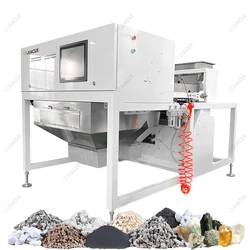

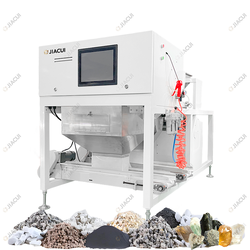

Classificador de Cor de Minerais CS-LA1200D

Identificar diferenças subtis em cor e forma, e detectar e remover substâncias de descoloração.

Menos consumo de combustível, força de remoção grande, alcançando alta precisão de remoção ultra, economizando combustível e energia!

Válvula solenoide com longa vida útil, o equipamento pode funcionar por muito tempo!

- CS-LA1200D

Working Principle Video

Watch how our color sorter performs efficient and precise sorting work

This video shows the working process of our chute color sorter in actual production environments. From material entry, optical recognition to precise sorting, it comprehensively demonstrates the high efficiency and accuracy of the equipment.

Improve Product Quality, Reduce Production Costs

Contact our expert team now to get exclusive solutions and preferential quotes

Free ConsultationTechnical Advantages

Our technical team has over 15 years of color sorter R&D experience, continuously innovating and leading industry development

Core Technology

- Multispectral Recognition Technology: Can capture visible and near-infrared spectra, identifying subtle differences that are difficult for the naked eye to distinguish.

- High-Speed Solenoid Valve: Response time less than 2 milliseconds, ensuring precise removal of defective products.

- Intelligent Algorithm: Image recognition algorithm based on deep learning, continuously optimizing sorting effects.

- Modular Design: Facilitates maintenance and upgrades, extending equipment service life.

As an industry leader, we have participated in formulating multiple color sorter industry standards and hold over 20 patents, providing professional sorting solutions to global customers.

Equipment Accessories

We provide comprehensive accessory support to ensure long-term stable operation of equipment

High-Precision Optical Sensor

Core component, responsible for capturing material color and shape information, ensuring sorting accuracy.

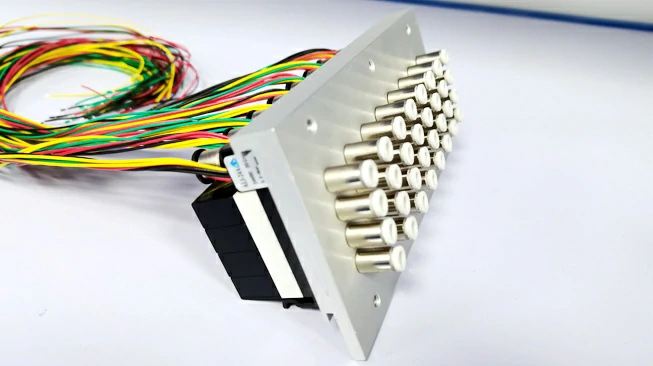

High-Speed Solenoid Valve

Fast response, precise removal of defective products, improving sorting efficiency.

Intelligent Control Panel

Intuitive operation interface, real-time monitoring of equipment status, facilitating parameter adjustment.

Wear-Resistant Chute Channel

Made of high-strength wear-resistant materials, extending service life and reducing maintenance costs.

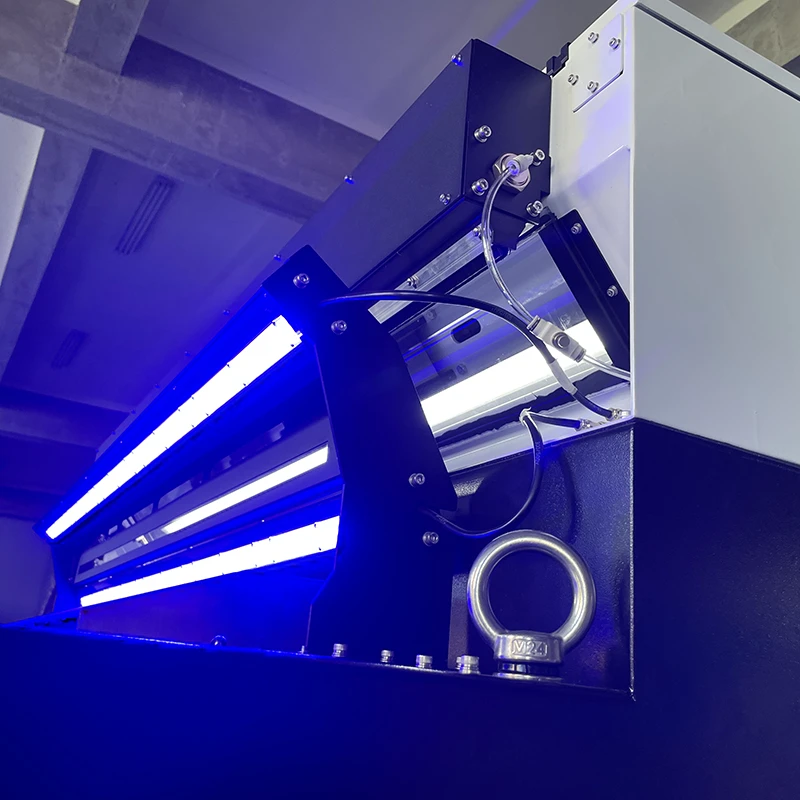

Energy-Saving LED Light Source

Provides stable and uniform lighting, reducing energy consumption and improving recognition accuracy.

Air Filter System

Keeps the equipment interior clean, preventing dust from affecting optical system performance.

Sorting Effect Display

Visually witness the excellent sorting effect of our color sorter

Precise Sorting, Enhancing Quality

Our color sorter can accurately identify and remove impurities and defective products from materials, with sorting accuracy up to 99.9%. The left side shows the material before sorting, containing various impurities and defective products; the right side shows the material after sorting, with impurities completely removed and product quality significantly improved.

| Modelo | Potência (Kw) | Fornecedor de Energia | Dimensões L*A*P (mm) | Peso (Kg) | Capacidade (T/H) | Precisão (%) | Taxa de Retenção |

|---|---|---|---|---|---|---|---|

CS-LA1200D | 9 | personalizável | 2810*2000*2088 | 2300 | 5-15mm 5-7T/H;15-30mm 6-10T/H;30-50mm 8-12T/H | ≥99,99 | >20:1 |

Note: The parameters in the above table are based on standard glutinous rice (with impurity content within 2%), and specific indicators may vary depending on the material and impurity content. Specifications and dimensions are subject to change without prior notice.

Customer Testimonials

Real feedback from global customers, witnessing our product quality and service level

JiaCUi's chute color sorter helped us solve long-standing quality issues, with sorting accuracy far exceeding expectations, and product qualification rate increased by 15%.

Manager Zhang

A Large Food Processing Factory

The equipment runs stably, is easy to maintain, and the after-sales service responds quickly, making it an indispensable part of our production line.

Engineer Li

A Mining Company

The return on investment is significant. After using JiaCui's color sorter, our raw material loss decreased by 8%, greatly improving economic benefits.

General Manager Wang

An Agricultural Product Processing Enterprise

Contate-nos

Preencha o formulário abaixo e a nossa equipa de profissionais entrará em contacto consigo no prazo de 24 horas.

Informações de contacto

- Zijing Network Science Parque.No.186 Heyang Road, Zona de Alta Tecnologia, Zhengzhou, Henan, China

- +86 16650275530

- sales@jiacuiworld.com

Inquire

Inquire

WhatsApp

WhatsApp

E-mail

E-mail