Introduction

In today’s competitive industrial landscape, efficiency and accuracy are the pillars of profitability. Every second lost on a production line can translate to significant revenue loss, while even minor defects can damage brand reputation. Enter high-speed industrial color sorters, advanced machines designed to maximize output, reduce waste, and ensure flawless quality.

Whether you’re processing nuts, grains, recyclables, or pharmaceuticals, high-speed color sorters are redefining operational standards. This article explores how these machines enhance industrial productivity, answers frequently asked questions, and provides actionable insights for businesses aiming to achieve peak efficiency and precision.

How High-Speed Industrial Color Sorters Work

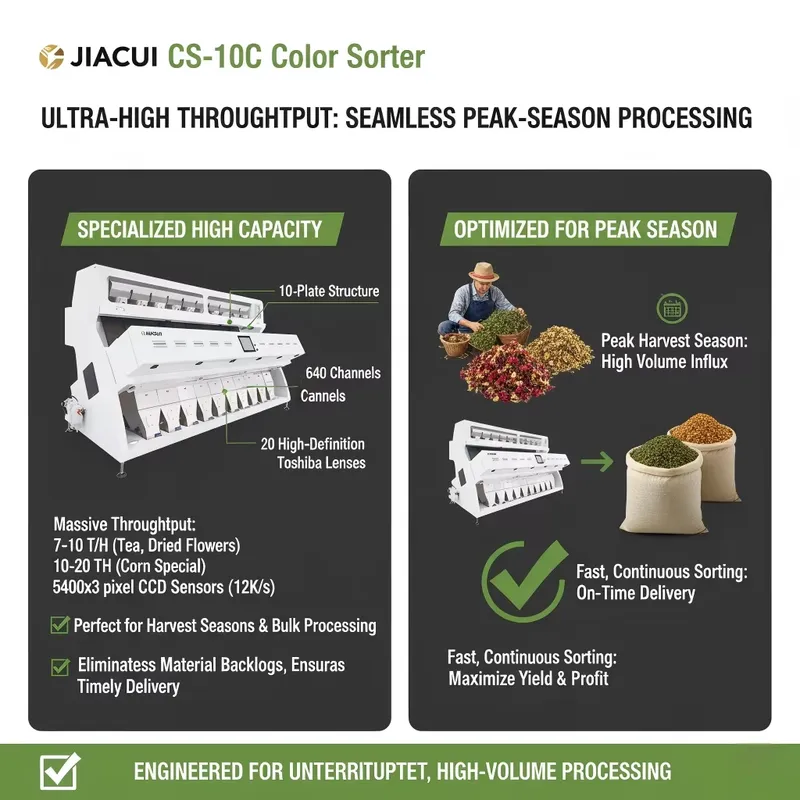

High-speed color sorters combine state-of-the-art optical technology with artificial intelligence, enabling the rapid inspection of thousands of products per minute. Unlike traditional sorting methods, which are labor-intensive and prone to human error, these machines offer consistent, automated, and lightning-fast sorting.

Advanced Imaging Sensors: High-resolution cameras detect subtle color variations, shapes, and textures.

AI-Powered Analysis: Machine learning algorithms instantly identify defects or foreign materials.

Precision Ejection Systems: Pneumatic or mechanical ejectors remove defective items in real-time, ensuring every batch meets stringent quality standards.

The result is unmatched speed, accuracy, and reliability, helping companies process more products without compromising quality.

FAQs About High-Speed Industrial Color Sorters

1. Which Industries Benefit Most from High-Speed Sorters?

High-speed color sorters are versatile tools for numerous industries:

Food & Beverage: Sorting nuts, cereals, fruits, and vegetables.

Recycling: Rapid separation of plastics, metals, and paper for maximum recovery.

Pharmaceuticals: Ensuring uniform color, shape, and size in tablets and capsules.

Textiles & Plastics: Classifying materials to maintain product consistency.

Industry reports indicate that the global industrial color sorter market is expected to reach $1.5 billion by 2028, demonstrating widespread adoption across sectors.

2. How Fast Are High-Speed Color Sorters?

Modern systems can process up to 20,000 items per minute, depending on product type and machine configuration. This speed allows companies to dramatically increase throughput without hiring additional labor or expanding facilities.

3. How Accurate Are These Machines?

Accuracy rates of up to 99.9% are achievable with high-speed color sorters. AI algorithms continuously learn from the production environment, improving defect detection and minimizing material loss.

4. Are High-Speed Sorters Cost-Effective?

Despite higher upfront costs, these machines quickly deliver ROI by reducing labor, minimizing waste, and increasing throughput. For example, a major nut processing plant reported a 25% boost in daily output and a 20% reduction in defective products after implementing high-speed sorters.

5. Can They Handle Complex Sorting Criteria?

Yes. Advanced models support multi-criteria sorting, such as color, size, shape, and even internal defects using spectral imaging. This flexibility ensures high-value products meet exacting standards.

Key Benefits of High-Speed Industrial Color Sorters

Maximum Throughput: Process more products in less time, optimizing overall output.

Superior Accuracy: Detect defects and contaminants invisible to the naked eye.

Cost Efficiency: Reduce labor expenses and waste simultaneously.

Consistency: Maintain uniform product quality batch after batch.

Scalability: Easily adapt to increased production demands without additional staff.

In industries where even a small defect can cause significant revenue loss, these machines are not optional—they are strategic assets.

Case Study: Maximizing Output in Grain Processing

A leading grain processor integrated high-speed color sorters into their production line. Results included:

30% increase in throughput

15% reduction in waste and rejected items

Substantial labor cost savings, allowing personnel to focus on value-added activities

This demonstrates how high-speed color sorters can transform production efficiency and positively impact a company’s bottom line.

Implementation Tips for Maximum Results

Operator Training: Ensure staff understands calibration, maintenance, and software operation.

Regular Maintenance: Keep cameras and sensors clean for optimal performance.

Data Analytics: Monitor performance metrics to continuously refine sorting parameters.

System Integration: Connect sorters with production management software for seamless operations.

Software Updates: Invest in machines with updatable AI algorithms for evolving accuracy.

By following these steps, manufacturers can maximize the efficiency and lifespan of their investment.

Future Trends in High-Speed Sorting Technology

The industry is evolving rapidly, with trends including:

IoT-Enabled Monitoring: Real-time performance tracking and predictive maintenance.

Enhanced AI Algorithms: Smarter defect detection for complex products.

Eco-Friendly Operations: Reduced waste and energy consumption across production lines.

Multi-Modal Sorting: Combining color, shape, size, and chemical composition for ultra-precise results.

Adopting these technologies now ensures a competitive advantage, as industries increasingly prioritize speed, accuracy, and sustainability.

Conclusion

High-speed industrial color sorters are game-changers for modern manufacturing. By combining AI-powered detection, precision ejection, and ultra-fast processing, these machines enable companies to maximize output, reduce waste, and maintain exceptional quality.

In a marketplace where speed and precision define success, investing in high-speed color sorters is not just strategic—it’s essential. Businesses that act now gain operational excellence, cost savings, and a distinct market advantage.

10 Tags:

high-speed color sorters, industrial automation, AI sorting machines, manufacturing efficiency, precision sorting, defect detection, production optimization, industrial throughput, smart manufacturing, quality control

5 Longtail Tags:

high-speed color sorters for grain processing, AI color sorting machines 2025, maximize industrial output with sorters, cost-effective industrial sorting solutions, precision defect detection technology