In the manufacturing industry, color sorting machines are an indispensable part of daily operations. These machines are also known as optical sorters, which first check for defects and contaminants in the raw materials. Then, they remove impurities and foreign matter, leaving only the purest and highest quality products.

Color sorter does not require manual sorting, compared to automatic color sorting, manual sorting is very time-consuming and extremely inefficient. The most common application is agricultural products, although many entrepreneurs use this labor-saving process for other bulk products.

JiaCui is the most advanced automation and detection system's Reliable source, providing comprehensive solutions to our customers. Our goal is to help you successfully manage profits while improving performance and reducing costs. Our color sorting machine provides a seamless workflow and improves productivity, while eliminating costly errors and slow, outdated processes.

Continue reading to learn more about the basics of automatic color sorting and shape size adjustment, and explore the features of our sorting technology series.

How does a color sorter work?

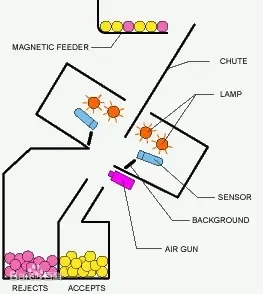

Color sorting machines utilize innovative technology to identify the characteristics of raw materials passing through their feed hopper as part of the bulk processing line .Firstly, the operator puts the material into the hopper, and vibrates it to move it into the chute. Then, pneumatic or mechanical ejection devices separate materials according to size and weight, and eject defective materials.

Next, the selected materials slide into the sorting room, the high-speed CCD chip performs precise, high-definition imaging, forming video signals for output and display, and completes sorting based on color differences. These machines identify and eliminate defective, imperfect, and diseased elements according to health requirements and the strictest food hygiene standards.

Different types of color sorting machines

Although manufacturers produce different types of color sorting machines, most belong to the following three main types:

Channel color sorting machine

An optical sensor array runs along the product chute of the sorting machine, these sensors operate simultaneously to ensure comprehensive and accurate detection. These machines can sort a large amount of materials quickly, making them an ideal choice for high-capacity production lines.

Belt color sorting machine

This type of sorter uses a conveyor belt to pass material through a single optical sensor .Since the objects do not move much, they are not easily broken, and many companies use this type of sorter to handle fragile items.

Optical color sorting machine

Optical color sorting uses lasers or cameras to automatically sort bulk products .This non-destructive testing machine can identify the structure, shape, size of defects, and chemical composition of products, and has a 100% inspection rate.

The main working principle of the color sorting machine

Then, what is the main working principle of the color sorting machine? Let's analyze it:

Firstly, the CCD color sorter determines the transmittance and color depth of the material in the hopper in the following ways:

- Take high-definition photos

- Compare the amplitude of the light source changes

- Eject materials with amplitude exceeding the predetermined value

Now, consider the second working principle: When the mechanical separation begins, the material must be evenly distributed to each channel .Then, the CCD camera in the sorting cabinet will detect the stable flow of products .After identifying the non-compliant material, the main control unit starts the spray valve, and the disqualified product accelerates into the defective bin.

The typical application of a color sorting machine

A color sorting machine is many Enterprises An indispensable part, especially in agriculture and the food processing industry. For example, color sorters can display seed images and quickly and efficiently sort grains and harvested products, including:

In addition, recycling, diamond, and mining industries, as well as many other companies, use them to sort minerals, sand, stone, and ore.

Standard components of a separator machine

Each color sorter has different functions, but the standard function of the color sorter is standard function of the color sorter from JiaCui Machinery includes:

- High-precision air jet

- Toshiba 5400 CCD Sensor

- Expected Lifespan of LED Reflective Light

- FPGA Processor

- Clear 15-Inch Color Touchscreen Interface

- AI Auto-Learning Feature

- Real-time Data Monitoring

- Highly Customizable Camera

The main components of the color sorting machine include the feeding system (material entering channel or trough), the main control unit, and the photoelectric system (including sorting cabinet, light source, camera, reflector, etc.).

When you choose JiaCui Machinery as your supplier, we promise you will obtain the most advanced equipment with advanced technology and seamless operation.

Common risks related to the use of color sorter machines

The economic and social benefits of color sorters are many, as their high efficiency and time-saving characteristics simplify agricultural sorting and prevent pollution and defects. However, this technology is not foolproof:

The accuracy of the inexpensive sorting machine is low: Certain low-quality color sorting machines may only achieve moderate accuracy in detecting impurities and defects.

Damaged items in the chute sorting machine: The color sorter often damages or destroys individual items while passing through the chute.

Normal wear: If not properly maintained and cleaned, the pressure source may damage machine performance. For example, some color sorters may be prone to issues with solenoid valves, such as leaks and incorrect movement.

The enterprise must invest in purchasing a color sorting machine that meets its needs and complies with industry regulations. Ensuring appropriate maintenance and service will extend the lifespan of the machine and its useful life.