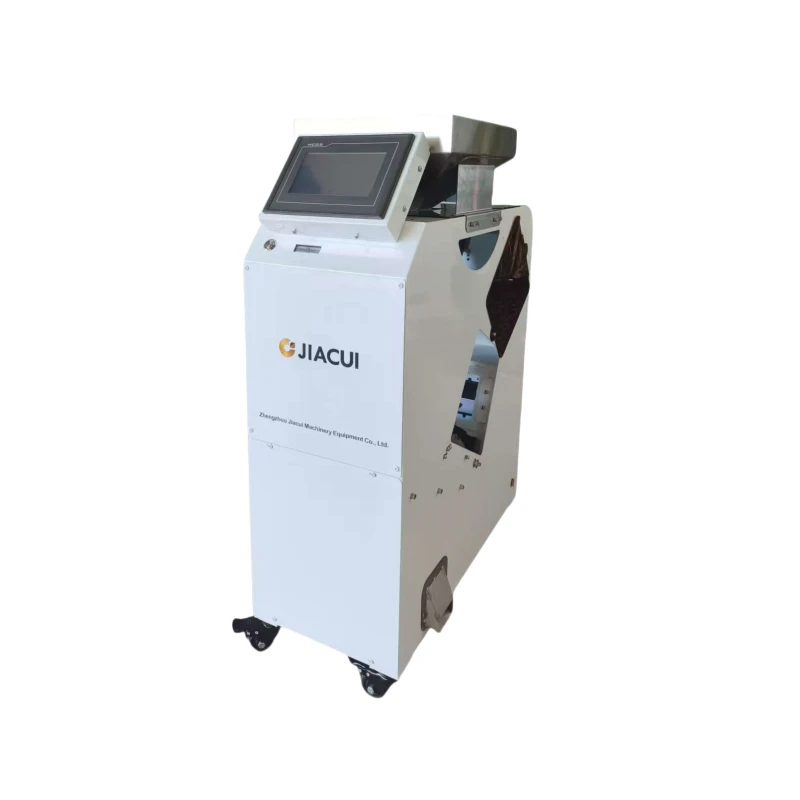

Product Overview

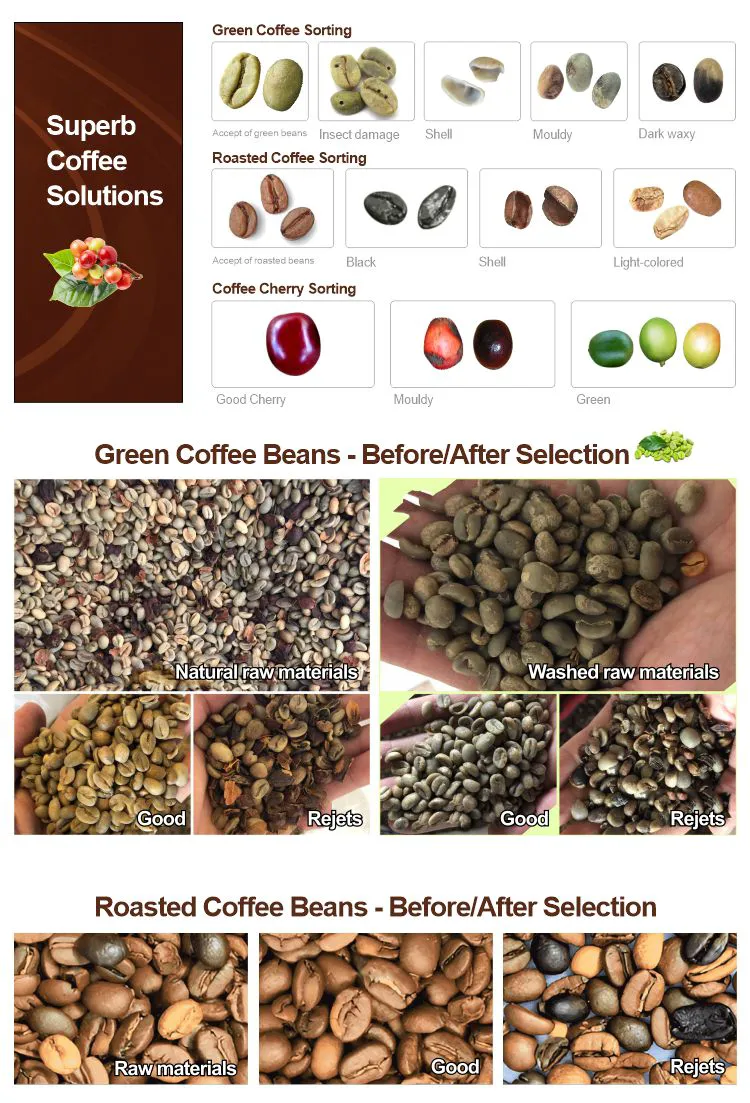

Our advanced Coffee Color Sorter is engineered to deliver the highest standard of purity for coffee processors and exporters. Utilizing high-resolution CCD cameras and cutting-edge AI deep learning algorithms, this machine precisely scans every single bean passing through the chute.

It effectively identifies and ejects defective beans—such as black, sour, immature, insect-bitten, and broken beans—that can ruin the flavor profile of a batch. Furthermore, it excels at removing foreign materials (FM) like stones, glass, and plastic, ensuring total food safety.

Whether you are handling green coffee beans prior to export or roasted coffee before packaging, our color sorter guarantees consistent uniformity. By automating the sorting process, you minimize manual labor costs while significantly increasing the market value and cup quality of your final product.

Product Parameters

| Model | Power(Kw) | Power Supply | Dimension L*W*H (mm) | Weight (Kg) | Capacity (T/H) | Accuracy (%) | Carryover Ratio |

|---|---|---|---|---|---|---|---|

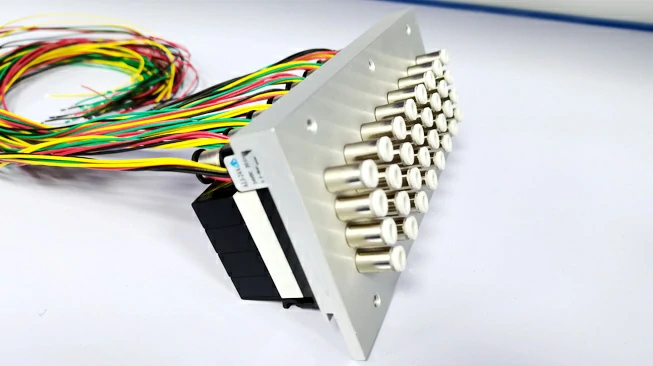

CS-QB16 | 0.2 | customizable | 330*700*1000 | 66 | 0.03 | ≥99.99 | >10:1 |

Note: The parameters in the above table are based on standard glutinous rice (with impurity content within 2%), and specific indicators may vary depending on the material and impurity content. Specifications and dimensions are subject to change without prior notice.

Core Advantages

High Sorting Accuracy

Up to 99.9% sorting accuracy, ensuring the highest product quality and consistency

Efficient Processing

High-speed sorting with a large capacity, significantly improving production efficiency

Advanced Technology

AI-powered sorting algorithm with RGB spectrum technology for precise identification

Easy to Operate

Intuitive control panel with wireless remote service support for convenient operation

Durable & Reliable

High-quality materials and components for long-term stable operation

Excellent After-sales

24/7 technical support and comprehensive maintenance services

Inquire

Inquire

WhatsApp

WhatsApp

E-mail

E-mail