Product Overview

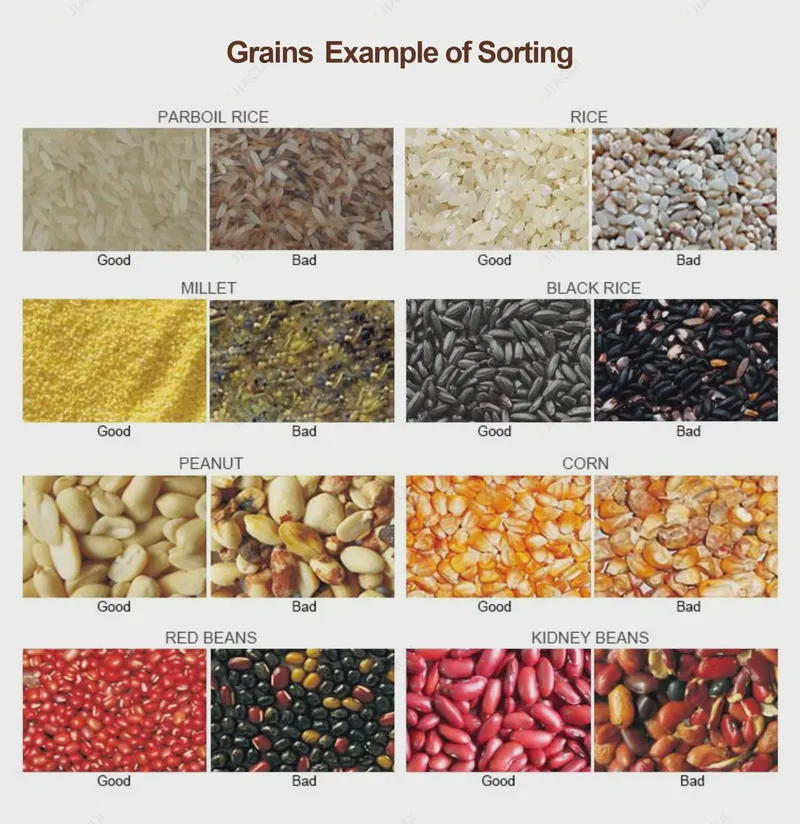

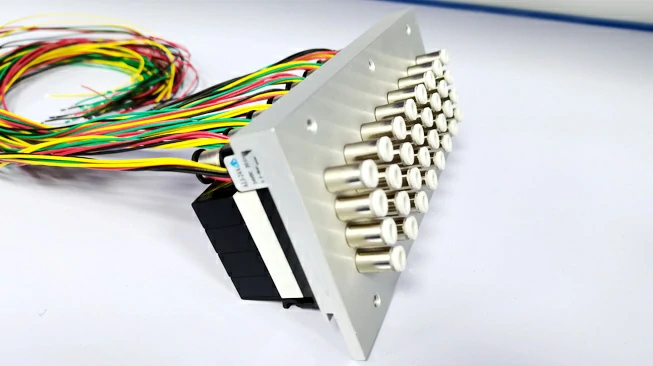

The rice color sorter is a crucial piece of equipment in the grain processing industry. It can automatically sort particles with different colors based on the optical properties of rice, using photoelectric technology, thereby improving the quality of rice and removing impurities. During operation, rice enters from the top hopper and slides down along the channel through the vibration of the vibrator. In the observation area of the sorting chamber, the system drives the solenoid valve to blow out particles with different colors according to the changes in light intensity and color, while the good products fall into the finished product cavity. It has powerful functions, capable of efficiently removing streaked rice, moldy grains, broken rice, as well as impurities such as glass and plastic. It is not only suitable for sorting various types of rice, but also performs excellently in sorting grains like millet and black rice. Moreover, it can meet the color sorting needs of more than 7,000 types of materials, including beans and medicinal materials. Compared with manual sorting, it saves labor and time, features high efficiency and low cost, and can effectively improve product quality and economic benefits.

Product Parameters

| Model | Power(Kw) | Power Supply | Dimension L*W*H (mm) | Weight (Kg) | Capacity (T/H) | Accuracy (%) | Carryover Ratio |

|---|---|---|---|---|---|---|---|

CS-12C | 7.5 | customizable | 4668X1595X2040 | 2600 | 8-12 | ≥99.99 | >10:1 |

Note: The parameters in the above table are based on standard glutinous rice (with impurity content within 2%), and specific indicators may vary depending on the material and impurity content. Specifications and dimensions are subject to change without prior notice.

Core Advantages

High Sorting Accuracy

Up to 99.9% sorting accuracy, ensuring the highest product quality and consistency

Efficient Processing

High-speed sorting with a large capacity, significantly improving production efficiency

Advanced Technology

AI-powered sorting algorithm with RGB spectrum technology for precise identification

Easy to Operate

Intuitive control panel with wireless remote service support for convenient operation

Durable & Reliable

High-quality materials and components for long-term stable operation

Excellent After-sales

24/7 technical support and comprehensive maintenance services

Inquire

Inquire

WhatsApp

WhatsApp

E-mail

E-mail